Contents

Machine plaster or manual – what is better? Being puzzled with this question, the beginner hurries to find the answer at construction forums where meets contradictory councils. The question, as a result, remains open, and it is necessary to solve a problem.

From for what it is possible a way to choose, not only the cost, but also duration of repair process and other parameters depends. Let's consider both options in more detail from the different parties. Let's roll!

What plaster is better manual or mechanized

For a start we will specify that we will understand "a machine way" as expression. We do not consider putting solution by means of the simplest devices, type of a hopper or just kartushny gun.

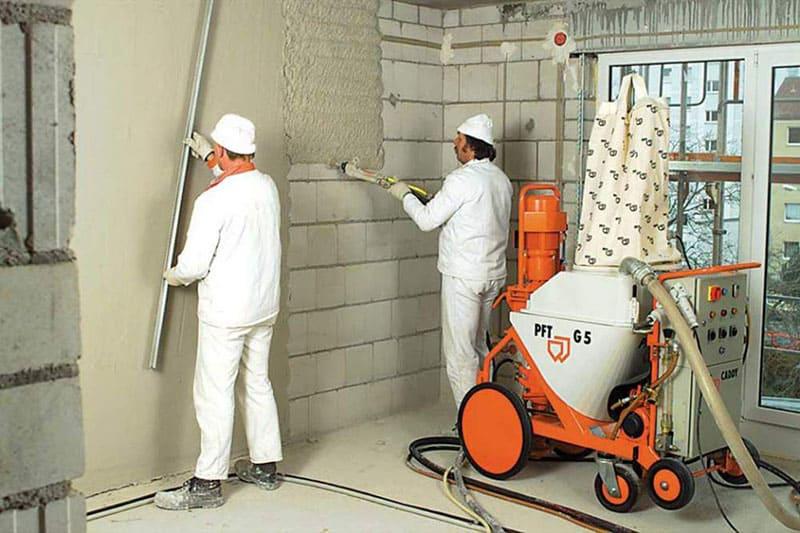

Let's compare a manual way (mix preparation, drawing on the basis are carried out by hands) and plastering at which solution preparation, its giving on a wall is made by the plaster car.

Ways have some coincidence and also a number of differences, we will consider the last, choosing, what is better.

We analyze the existing distinctions by several criteria.

- When plastering facades of one-storey buildings a scaffolding or the construction woods which are not required at the mechanized plaster are manually necessary if the surface of "fur coat" is not smoothed down.

- Audit of a condition of a wall, old covering and other preparatory operations of differences have no.

- Beacons for manual processing can be mounted with a step of 1.2-1.5 m. For machine putting solution a step of beacons – no more than 1 m.

- The cost of dry plaster mixes (CC) for cars is less.

- Productivity of mechanical drawing is 3 times higher (minimum).

- The consumption of plaster materials at manual work is higher.

- The quality of a covering after mechanical plastering is higher due to achievement of uniform consistence, uniformity of drawing, a solution pridavlivaniye by force of a nabryzg.

- Need for the equipment. At manual plastering ordinary tools of the plasterer are necessary. At the mechanized imposing are necessary the machine station (or the plaster car), the compressor giving a gun, hoses.

- The labor input is higher at manual drawing.

- Works upon completion of putting solution.

- Level of necessary professionalism. Mechanical plaster demands compulsory education, special preparation.

As you can see, solving, the mechanized or manual plaster of walls is more preferable, it is necessary to consider a lot of things.

The mechanized plaster of walls pluses and minuses

Let's fluently consider how process of machine plaster proceeds.

- As it is told above, preliminary preparation and also priming of the basis are performed the same as similar stages at manual causing structure.

- Prepare "machinery" for performance of work (connect the machine, hoses, the compressor, water, set up the equipment).

- Fill up CC in the reception bunker. The car, mixing water with mix, begins to make solution weight.

- The plasterer, holding a spray head, applies with ranks solution on a wall. The operator services the station.

- The laid solution is leveled the rule (during the interior works).

- Upon completion of putting mix "machinery" is cleaned, sorted, dried.

- Withdraw beacons, closing up flutes manually.

Builders can apply also the mixes which are not intended for mechanical plaster however have to take all measures to exclude hit of large fraction of filler or knitting and also low-quality components.

The list of advantages of the mechanized plaster is impressive:

- As preparation of working mix is carried out in the car, dust formation is indoors minimum.

- CC for machine plastering are cheaper therefore means when purchasing factory structures are saved.

- The solution consumption many times is less, than at manual plaster. Besides – economy.

- The weight thrown under pressure lays down more densely and is more tenacious keeps on the basis.

- When drawing at the expense of the involved air the covering "sated" with a time through which walls breathe better and is formed the necessary microclimate is indoors supported.

- Due to increase in porosity the ability of a covering to hold warmly increases.

- Probability of shrinkage of the put layer goes down that attracts decrease in a possibility of cracking and emergence of chips.

- Dense drawing increases the covering durability (when screwing self-tapping screws material does not crumble).

- After alignment the layer does not demand a shpaklevaniye (treats only plaster structures).

- The quality of the plaster "dough" made by screws of the car is higher. The car stores in memory of data on proportions of different structures. It is enough to operator to choose the mode.

- Small number of workers (but not less than two, and are more often than three people).

- Low cost of works. Pay attention (the speech not about the price).

- The covering laid by car serves longer.

Minuses of machine plaster:

- Expensive equipment is used to performance of work, hiring of team of experts is required.

- Part of plaster cars demands three-phase connection that is not on each object.

- The power consumption is increased.

- When spraying indoors perhaps strong pollution.

- The period of possible performance of work because of the noise made by mechanisms is narrowed. At night or it is impossible to carry out plastering in the evening.

- The machine and the compressor demand service just before and after plastering. It is also necessary to wash out, dry the equipment upon termination of work.

- To plaster curvilinear surfaces (for example, columns), the method is not suitable.

- Special corners for plastering by car of internal corners are necessary.

- Features of putting solution lead to creation of the covering demanding long drying. Finishing finishing of walls is possible only a week later after completion of plastering.

- Also features of the created layer affect a possibility of facing by a tile. The tile keeps badly, over time is unsnapped.

- On cement mixes the capacity of the machine goes down.

- Placement of the compressor, ShM and hoses requires a lot of place that lacks in small rooms.

Manual plaster of advantage and shortcomings

It is possible to study technology of performance of plastering in details in articles of the section "Plastering".

We will review the sequence briefly:

- Preparation of the basis.

- Mix preparation (with use of the mixer or a rastvoromeshalka).

- Installation of beacons.

- Putting solution (from 1 to 3 passes).

- Zatirka.

- Dredging of mayachny profiles, seal shtrob.

- Shpaklevaniye.

- Drying before finishing finishing.

The list is plus:

- Even the beginner, having trained, it is capable to apply plaster solution manually on the basis with ordinary plaster tools.

- The expensive equipment is not necessary.

- Possibility of stage-by-stage conducting repair (when not all house, but certain rooms needs updating).

- It is possible to work in any time, convenient for the owner, including at night.

- Possibility of plastering and careful processing of remote sites, curvilinear surfaces.

- Possibility of direct control and adjustment during each of operations.

- It is less than difficulties with selection of components for mix (the structure is selected independently).

- It is simpler to find performers.

- As solutions prepare small parties, it is easier to pass from plaster structures to cement (for example, for plastering of the bathroom after kitchen or the living room).

Minuses:

- Manual work is more labor-consuming, than mechanized. Big physical activities. When plastering the big areas for the purpose of acceleration of works more workers will be required.

- Preparation of structures of three types is required (an obryzga, basic – soil, a nakryvka).

- Big consumption of plaster materials.

- Small productivity.

What is cheaper

To compare that will be more expensive – machine or manual plaster, it will be required to execute difficult calculations. In practice profitability of machining depends on the size of the plastered areas. The more the areas, the are more profitable.

What it is better to choose and in what case

Manual will help to facilitate the choice between machine plaster or the table in which each plus or minus is considered.

| The compared criteria | Way of plastering | |

|---|---|---|

| mechanical | manual | |

| Quality of solution | Above, consistence more evenly | Depends on skill, in general, concedes |

| Mix consumption | More economically | Depends on skill |

| The used structures | Special mixes of factory production on a plaster or cement basis | Acquired by CC on the same bases, however, the choice is broader. It is possible to prepare solution, selecting components independently |

| Restrictions | Because of noisiness it is impossible to apply in hours of "silence" | any |

| Unfitness for curved surfaces, remote sites | There are no restrictions | |

| The lack of the three-phase power supply network narrows the choice of brands of the equipment | There are no restrictions | |

| It is not applied at subzero temperatures | In case of subzero temperatures use winter plaster | |

| Special training and the acquired experience is required | It can be carried out by beginners after the small training | |

| In small rooms it is impossible to place the equipment | There are no restrictions | |

| Problems with use under a tile | There are no restrictions | |

| Plastering terms | Drawing is carried out quicker, drying – longer | At the small areas the master is capable to process a surface almost with the same speed. Loss at big surface areas. |

| Productivity of works | above | below |

| Quality of a covering | In general above | Depends on skill, in general, below |

| Application | Universal (for interiors and facades) | universal |

Whether it is possible to apply machine plaster manually

As machine plaster of walls is carried out by special mixes which cost a time 30% cheaper, there is this quite reasonable question.

Such mixes can be used for manual drawing, but emergence of problems is possible:

- At selection of proportions it is difficult to determine correctly at once the volume of the added water (producers do not specify it as parameters are put in ShM). To find out the correct proportions, it will be required to part first CC by eye. Such experience demands time and increases a material consumption.

- For the plasterer with experience upon transition to machine mix there will be unusual terms of a skhvatyvaniye and drying of structure, its plasticity. It is necessary "to be retrained" that also extends process.

- On counters there were counterfeit mixes which quality is not checked. Especially this problem of branded brands concerns.

- Be not bought on an opportunity to save, buying expired mixes. First the wall after plastering can look good. And all troubles will be shown over time.

As you can see, to solve for itself: machine plaster or manual, what is better? – multidimensional task. In each case the answer can be various. If it is not possible to decide on the choice independently, address the credible experts.

(yet there are no estimates)

(yet there are no estimates)

Primer of walls before plaster – the help in the choice of suitable structure

Primer of walls before plaster – the help in the choice of suitable structure

What heater to choose for house walls outside under plaster

What heater to choose for house walls outside under plaster